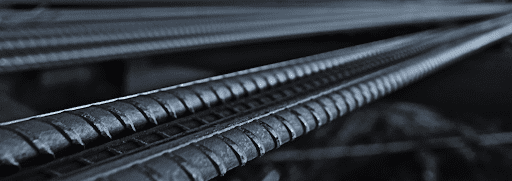

Thermo Mechanically Treated (TMT) Bars are the backbone of modern construction. Their superior performance is a result of a specialised manufacturing process that involves rapid cooling after heating, resulting in a unique combination of strength and ductility. This makes TMT bars the preferred choice for engineers and builders across the globe. To make an informed decision, one must know the different types of TMT bars.

To cater to the diverse needs of construction projects, different types of TMT bars are produced in various grades. Here, we will dive into understanding the commonly used grades of TMT bars and their unique benefits, so that you can make an informed decision of choosing the right types of TMT bars for your requirements.

Let’s get started!

Different Types of TMT Bars

1. Fe 415

Fe 415 is a popular grade of TMT bars widely used in the construction industry. The bars of these grades are reasonably tensile strong and have good ductility, with a yield strength of 415 MPa.

Due to their lower strength, Fe 415 TMT bars may not be the ideal choice for high-rise buildings or structures subjected to heavy loads, thus are utilised in small-scale construction projects. They are mostly preferred to be used in areas that are prone to natural disasters, especially earthquakes. While numerous qualities of this grade are quite useful, there are also some disadvantages to it.

Compared to higher grades, Fe 415 TMT bars have a lower yield strength. This means they may require a larger cross-sectional area to provide the same structural capacity, potentially leading to increased material costs.

2. Fe 500

Fe 500 TMT bars are a grade of TMT bars extensively and popularly used in the construction industry. They have a minimum yield strength of 500 MPa. They are appropriate for usage in structural components that withstand a heavy load. They also provide a decent mix of flexibility and tensile strength. The bars of these grades are Ideal for bearing heavy loads in construction. They also have great weldability, which means that these bars can be easily joined with other steel components.

3. Fe 500D

These types of bars are a variant of the Fe 500. While Fe 500 is a common grade, this grade is considered to be even more ductile. They are widely used in construction projects due to their exceptional strength and durability. Fe 500D TMT bars deliver a perfect combination of strength and ductility, especially for structures in high seismic zones or where flexibility under movement is vital. These bars also exhibit excellent fire resistance, helping to maintain structural integrity during fires.

4. Fe 550

Fe 550 TMT bars are high-strength, earthquake-resistant steel bars used in construction. They are known for their excellent tensile strength, ductility, and corrosion resistance. They have a better and higher load-bearing capacity with a yield strength of a minimum of 550 MPa. The higher strength of this grade of bar allows for the use of fewer bars, reducing material costs and construction time.

Fe 550 bars are also quite easily weldable, facilitating efficient construction processes. Also, while these bars may have a slightly higher initial cost compared to traditional steel bars, their long-term durability and reduced maintenance costs can make them a more cost-effective choice.

In all, Fe 550 TMT bars offer a combination of strength, ductility, durability, and weldability, making them a preferred choice for various construction projects, especially those requiring high structural integrity.

5. Fe 550D

A variant of the Fe 550 grade bars, the Fe 550D bars offer a combination of strength and ductility that makes them ideal for structures that need to withstand seismic forces. Possessing excellent fatigue resistance, these bars can endure repeated stress cycles without failing, making them suitable for applications like bridges and industrial structures.

The ‘D’ in Fe 550D signifies its increased ductility. This means it can undergo significant deformation without fracturing, making it more resilient to seismic activities and other sudden loads. The durability and resistance to corrosion of these bars reduce the need for frequent maintenance and repairs, further contributing to long-term cost-effectiveness. Though the mechanical properties of Fe550 and Fe550D are the same, the high adaptability capacities of Fe550D bars make them a superior choice at times.

6. Fe 600

Fe 600D TMT bars are high-grade reinforcement bars that are commonly used in construction projects due to their exceptional strength and durability. The bars of these grades have a higher yield strength in comparison to traditional TMT bars, allowing them to withstand greater loads without deforming. These bars are engineered for superior strength and durability and are essential for specialised applications such as high-strength concrete construction and critical infrastructure like nuclear power plants and chemical factories.

In some regions, Fe 600 bars may be less readily available and they might generally be more expensive, adding to increased costs. The higher strength of Fe 600 bars may require more specialised handling and fabrication techniques. This could add to the increasing labour costs.

Conclusion

It is quite essential to choose the right grade of TMT bars to match your product requirements. By understanding the various grades of TMT bars, one can make an informed decision to suit their needs.

The high-quality TMT bars by Jumbo TMX of the grades, Fe500, Fe500D, Fe550, and Fe550D are meticulously crafted to ensure optimal performance and reliability in any and every construction project. Choose from a wide range of sizes ranging from 8mm to 32mm, to meet the specific requirements of your application. Choose JUMBO TMX for unmatched strength and ductility.