For concrete constructions to have structural integrity, steel reinforcement bars are necessary parts of contemporary construction. They serve as the concrete’s skeleton, supporting it and keeping it from breaking or crumbling under pressure. It is therefore crucial to understand the types of steel reinforcement bars that would work best for their needs. A project’s structural integrity, safety, and cost-effectiveness are all impacted by the choice of reinforcement bars, which range from the conventional deformed bars used in many residential and commercial buildings to the high-strength bars used in vital structures like bridges and dams.

There is a vast range of reinforcement bars, each with its own unique qualities and uses, so understanding the many kinds of reinforcement bars and how they are used in modern construction is crucial to making an informed decision.

Types of Steel Reinforcement Bars

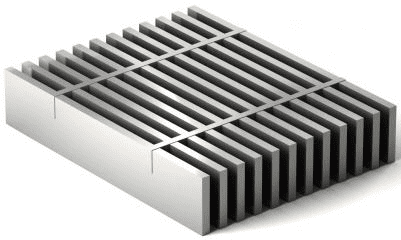

1. Cold Rolled Steel Bars

Cold-rolled steel bars are the type of steel bars that have been processed through a rolling mill while they are cold. This means that the steel is not heated up during the process. Cold-rolled steel often has a smoother surface and also allows for greater precision in terms of size and shape. They are most commonly used in structures where high strength and a smooth finish are required, such as bridges and buildings. But sometimes cold rolling introduces residual stresses into the material, which can affect its performance in certain applications.

2. Pressing Steel Bars

Pressing steel bars is a common manufacturing process that involves applying force to deform the metal into a desired shape. Different techniques are used to make pressing steel bars, they include practices like forging, extrusion, stamping and bending. The process of pressing steel bars at times can be energy-intensive, leading to higher operational costs.

Pressed steel bars are used in various construction applications, such as reinforcing concrete structures, creating structural frames, and manufacturing building components and even the automotive industry relies heavily on pressed steel components.

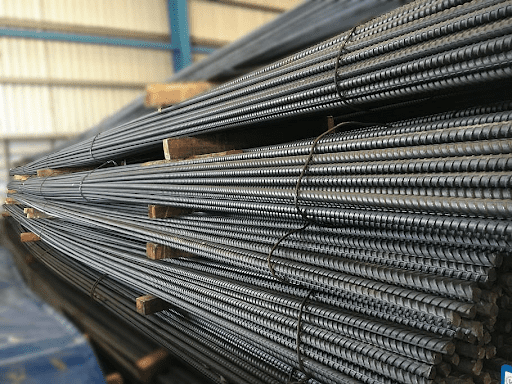

3. Thermo-Mechanically Treated (TMT) Bars

TMT bars are quite a popular choice for building structures. They are manufactured through a unique process that involves heating the steel/ billets to a high temperature, quenching it rapidly in water, and then tempering it. This process creates a tough outer layer and a softer core, providing excellent tensile strength and ductility. These properties of superior strength, ductility, and seismic resistance make them a reliable and safe option for reinforcing concrete structures.

TMT bars have a higher tensile strength than traditional steel bars, which means they can withstand greater loads without breaking. Not just this, TMT bars have a special ribbed design that helps them bond more strongly with concrete, which improves the overall strength and durability of the structure.

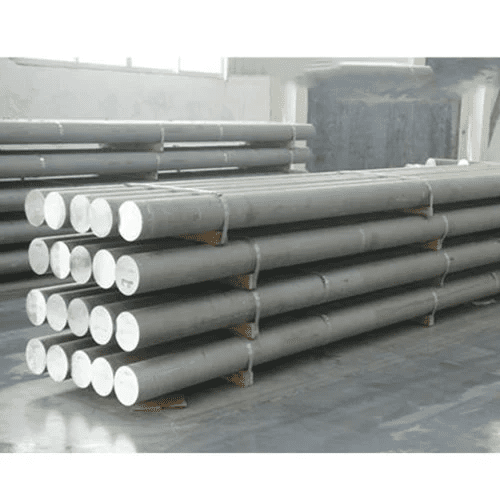

4. Mild Steel Bars

Mild steel bars are a versatile and widely used type of steel that is primarily composed of iron and a small amount of carbon. This composition gives these bars their characteristic toughness and malleability.

Mild steel bars come in various sizes and shapes and are often used as reinforcement in concrete structures, such as beams, columns, and slabs. They help to increase the structural integrity of the concrete by providing tensile strength, but it needs to be noted that these bars are also prone to rusting and corrosion when exposed to moisture or harsh environments.

5. Carbon Steel Bars

Carbon steel bars are one of the most commonly used types of bars due to their versatility and affordability. Their composition mainly comprises iron and carbon, with a small percentage of other elements like manganese, silicon, phosphorus, and sulphur. These bars are extremely ductile and this property allows for shaping and forming the bars into various shapes and sizes without breaking. They are the primary material for manufacturing car frames, axles, and other structural components. Also note that carbon steel bars can be relatively heavy, which can increase transportation and handling costs.

Conclusion

The selection of the appropriate rebar type depends on several factors, including, structural requirements, environmental conditions, cost considerations and even aesthetic preferences and by carefully considering these factors, professionals can optimise the performance and longevity of their structures. By understanding the different types of steel reinforcement bars and their applications, engineers and contractors can make informed decisions to ensure the structural integrity and durability of their projects.

For applications requiring exceptional strength, durability, and seismic resistance, Jumbo TMT bars are an excellent choice. These bars offer superior performance and reliability. They are widely used in critical structures, such as high-rise buildings, bridges, and dams. So, if you are looking for the perfect reinforcement bar for your construction needs, choose JUMBO TMX.