Out of the many reinforcement materials available in the market, selecting the ideal one is vital for every construction project. These materials ensure your home is durable and withstands all the different pressures and challenges it might encounter over the years. Let’s walk through five essential reinforcement materials.

5 Essential Reinforcement Materials

1. TMT Bars

TMT Bars are a pillar of modern construction. TMT stands for thermomechanically treated. They’re made through a special process where steel bars are heated and then cooled down quickly.

This process gives the bars the following remarkable advantages:

- Strength: TMT bars boast exceptional strength, supporting structures to withstand natural calamities.

- Flexibility: Their ability to bend without breaking is essential for earthquake resilience.

- Durability: Corrosion resistance ensures longevity, reducing the need for frequent repairs.

Why Choose TMT Bars?

Engineers and builders favor TMT steel bars for their reliability and cost-effectiveness. They maximize building safety, minimize structural damage risks, and offer long-term savings by extending the lifespan of projects.

TMT bars are indispensable in building infrastructures such as buildings, bridges, roads, and dams, thanks to their unmatched qualities. They are the preferred choice for projects demanding the highest standards of safety and longevity.

2. Concrete

Concrete, known for its robustness and long-lasting nature, plays a crucial role as a core reinforcement material in building projects. It forms the essential support for structures, including foundations, walls, and floors, ensuring a solid foundation for any construction.

However, for enhanced resilience, especially in regions vulnerable to earthquakes or significant weight, combining high-quality TMT bars with concrete is a superior strategy. TMT bars offer added flexibility and tensile strength, making structures safer and more durable than concrete alone.

3. Epoxy-Coated Carbon Steel Bars

Epoxy-coated carbon steel bars are essentially carbon steel rebars coated with a protective layer of epoxy. This layer acts as a barrier against moisture and salts, helping to prevent corrosion.

This type of reinforcement material is commonly used in road and bridge construction, parking structures, and marine facilities, where protection against corrosion is important but the environment might not be as aggressive as to warrant the use of stainless steel or FRP.

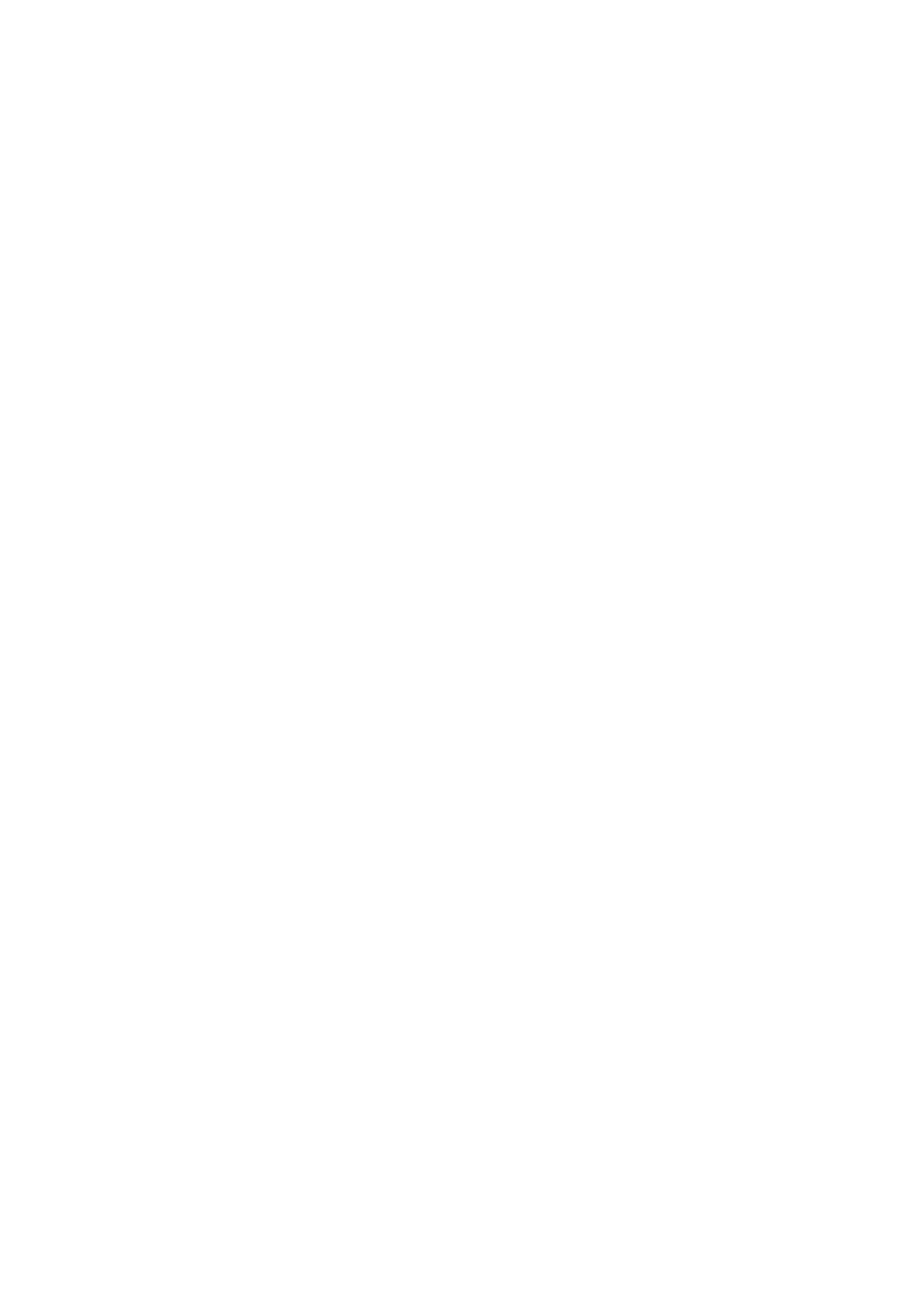

4. Wire Mesh

Wire Mesh is made from woven or welded wires. The primary role of wire mesh is to reinforce slabs, walls, and pavements, ensuring these structures are stronger, more durable, and less prone to cracking.

By evenly distributing stress throughout the wire mesh, it prevents the formation of large cracks. This is how it effectively manages the natural expansion and contraction over time and under various loads.

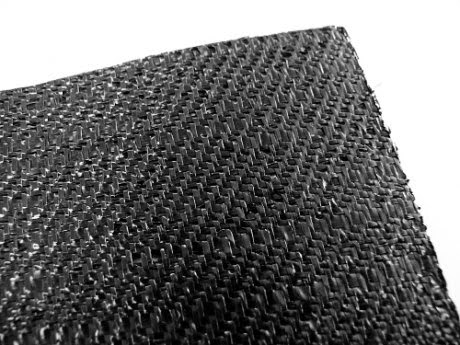

5. Geotextiles

Geotextiles, when used as reinforcement materials, greatly improve the soil’s mechanical strength, making it better suited for a wide range of construction projects. They play a key role in stabilizing slopes, strengthening structures that hold back the earth, and boosting the ability of pavements and foundations to support more weight.

Geotextiles distribute stress evenly and boost soil cohesion, thereby increasing the durability and safety of infrastructure projects like highways, railways, embankments, and retaining walls. This makes them an essential element in contemporary engineering and construction efforts.

Features of Reinforcement Materials

The table below outlines the key characteristics and applications of all the reinforcement materials we talked about above. It will help you choose the best for your construction projects.

| Feature | TMT Steel Bars | Concrete | Epoxy-Coated Carbon Steel | Wire Mesh | Geotextiles |

| Material | Steel | Base material | Epoxy-coated carbon steel | Steel wires | Synthetic fibers (Polyester, Polypropylene) |

| Strength | Very High | Moderate to high (compressive) | Moderate | Moderate | Low |

| Stiffness | Moderate | High | Moderate | Moderate | Low |

| Corrosion Resistance | High | Moderate (susceptible in harsh environments) | Good | Low | NA |

| Cost | Moderate | Low | Moderate | Low | Low |

| Weight | Heavy | Heavy | Moderate | Light | Light |

| Flexibility | High | NA | Moderate | Low | NA |

| Applications | General construction (buildings, bridges, pavements) | Used as the primary structural material in various applications | Moderate corrosive environments, improved bond | slabs, walls, and pavements | Soil reinforcement, filtration, drainage |

Conclusion

In the world of construction, the choice of reinforcement material plays a pivotal role in defining the strength, durability, and longevity of a structure. Whether it’s the versatility of wire mesh or the innovative application of geotextiles, each material offers distinct advantages.

However, for foundational strength and resilience, opting for high-quality TMT bars from Jumbo TMX remains unmatched. These bars not only ensure the structural integrity of projects but also contribute to their sustained performance over the years, making them a wise choice for builders and engineers alike.