Different types of structures require different types of beams in construction. Every builder must know the kind of beam their project needs to attain the best structural outcomes.

TMT bars are indispensable in the construction of concrete beams. They work hand in hand with various types of beams to create a composite structure that is exceptionally strong and durable.

So let us dive into types of beams in construction that give us an idea of their purpose and enable a builder to make the perfect choice for their work.

Types of Beams in Construction

1. Simply supported beam

A simply supported beam has support on both of its ends. The two main types of supports used for this type of beam are pinned support and roller support. These supports allow for rotation at the connection points but prevent vertical movement. This beam type is used especially for constructing balconies, crane arms, etc.

TMT bar types and sizes used for simply supported beams:

- Fe 500: The most widely used grade for simply supported beams in buildings due to its excellent balance of strength, ductility, and cost-effectiveness

- Fe 550D: Suitable for heavy-duty applications where enhanced strength and ductility are required.

- Typically, TMT bars ranging from 10mm to 25mm in diameter are used. However, for heavier loads or longer spans, larger diameters might be necessary.

2. Rectangular beam

The rectangular beams have a long and slender structure with a rectangular cross-section. These types of beams in construction are used as they distribute weight across their surface and can also bear a good amount of weight. They are fundamentally used while building floors, ceilings, roofs, bridges, etc.

TMT bar types and sizes used for rectangular beams:

- Fe 500: Offers higher strength and is used in medium to high-rise structures.

- Fe 550D: Ideal for high-rise buildings and structures subjected to heavy loads.

- 12mm, 16mm, 20mm, and 25mm: These are the most common sizes used in residential and commercial buildings.

- Larger sizes (32mm, 36mm): Used for heavy-duty structures like bridges, dams, and industrial buildings.

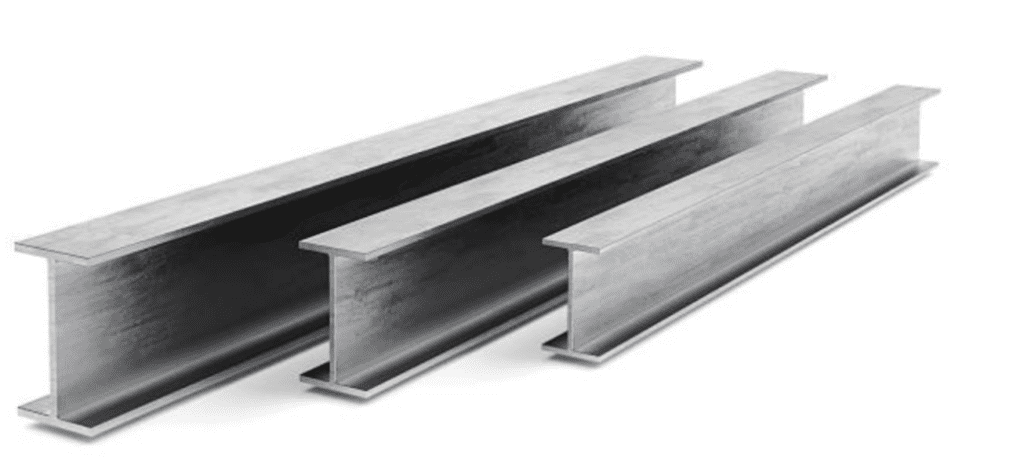

3. I beam

These beams are normally made from structural steel, due to which these beams are quite durable. The cross-section of such beams resembles the shape of the letter ‘I’, thus its name. These types of beams in construction are used for large-scale constructions as their shape makes them efficient at resistant bending.

TMT bar types and sizes used for I beams:

- Fe 500: Offers higher strength and is suitable for heavier loads.

- Fe 550D: Provides even higher strength for demanding applications.

- Main reinforcement: Typically uses larger diameter bars (16mm, 20mm, or 25mm) placed at the top and bottom flanges of the I-beam to resist bending stresses.

- Shear reinforcement: Smaller diameter bars (10mm or 12mm) are used to resist shear forces.

4. Angle or L beam

These versatile structural elements can bear a tremendous amount of load and have a cross-section that resembles the letter ‘L’, thus its name. These types of beams in construction are used generally for framing structures or creating corners, due to their rigidity, sturdiness and strength.

TMT bar types and sizes used for angle or L beams:

- Angle beams are not typically reinforced with TMT bars as they are standalone steel sections.

5. Wooden beam

These types of beams in construction are long and horizontal structural elements that are used in buildings and other structures to support loads. While typically they are made from solid wood, they can also be made from engineered wood products like glulam or LVL.

TMT bar types and sizes used for wooden beams:

- TMT bars are steel reinforcements specifically designed for strengthening concrete and thus are not used for wooden beams.

6. Compound beam

These types of beams in construction are formed by rigidly connecting two or more separate beams together so they act as a single unit. This is done to gain additional strength or rigidity or any other property that cannot be achieved with a single beam of a specific material.

TMT bar types and sizes used for compound beams:

- Fe 500: Offers higher strength and is suitable for structures subjected to moderate to high loads.

- Fe 550D: Provides even higher strength and is often used in demanding applications like bridges and high-rise buildings.

- 16mm to 25mm: Commonly used for the main reinforcement.

- 20mm to 32mm: May be required for heavier loads.

- 8mm to 12mm: Typically used for stirrups to resist shear forces.

7. Trussed Beam

These beams are typically very stiff and very strong and come in very essential during construction of heavy structures like buildings and bridges. Triangles strengthen these types of beams in constructions to span long distances without needing to be thick.

TMT bar types and sizes used for trussed beams:

- Fe 500: Offers good strength and ductility, suitable for most general construction applications.

- Fe 550D: Provides enhanced ductility, which is beneficial in areas prone to seismic activity or where additional flexibility is required.

8. Cantilever beam

This type of beam is fixed at one of the ends and then simply extends towards the space at the other end. Due to the unsupported end, cantilever beams may experience a bending moment when loads are applied on the free end. They usually require a very strong back or holding to support them. These types of beams in construction give a very unique look to our structure.

TMT bar types and sizes used for cantilever beams:

- Fe 500: A versatile grade suitable for most residential and commercial constructions.

- Fe 550: Offers higher strength and is often preferred for larger spans or heavier loads.

- Fe 550D: Specifically designed for enhanced ductility, making it a good choice in seismic zones.

- 16mm, 20mm, 25mm to resist bending moment.

- Smaller diameter bars (12mm, 16mm) for additional reinforcement.

- Smaller diameter bars (8mm, 10mm) to enhance shear strength.

9. Reinforced concrete beam

Made from combining steel and concrete, these types of beams in construction are widely used. Steel and concrete are combined to achieve a structural property that is the combination of the best of both worlds. These beams can resist both, compressive and tensile forces.

TMT bar types and sizes used for reinforced concrete beams:

- Fe 550 and Fe 550D: Offers higher strength, ideal for structures with heavy loads.

- Smaller beams in residential or light commercial buildings often use 10mm, 12mm, or 16mm bars.

- Larger beams in commercial or industrial structures may require 16mm, 20mm, or even 25mm bars.

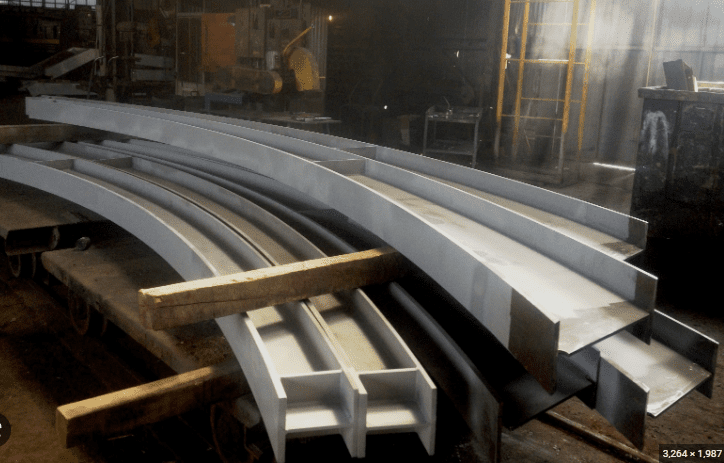

10. Curved beam

These types of beams in construction are those that do not have a straight axis, but instead have a curved centerline. They are used in structures like roofs and arches, etc,. where straight beams might not be able to deliver the necessary shape, support or looks.

TMT bar types and sizes used for curved beams:

- Fe 500: Provides a good balance of strength and ductility. Suitable for most curved beam applications.

- Fe 550 and Fe 550D: Offers higher strength, making it ideal for beams subjected to severe bending moments or dynamic loads.

- 8mm to 12mm: For smaller beams and lighter loads.

- 16mm to 20mm: For medium-sized beams with moderate loads.

- 25mm to 32mm: For large beams and heavy loads.

Conclusion

Choosing the right beams ensures that any structure is stable, durable and safe. So, make a choice that will preserve your structure for generations to come.

Each type, from the simply supported beam to the intricately curved beam, serves a distinct purpose and contributes uniquely to a structure’s integrity. By understanding the characteristics, applications, and reinforcement requirements of different beams, builders can make informed decisions that optimise structural performance, safety, and durability.

The relationship between TMT bars and various beam types helps in understanding the importance of material selection in achieving optimal results. By carefully considering factors like load-bearing capacity, aesthetic requirements, etc, builders can create structures that stand the test of time.

If you are looking to create structures that stand the test of time, choose JUMBO TMT Bars. Jumbo offers a range of high-quality TMT bars including Fe500, Fe500D, Fe550, and Fe550D. These TMT bars are available in sizes ranging from 8mm to 32mm, making them suitable for a wide range of construction applications.