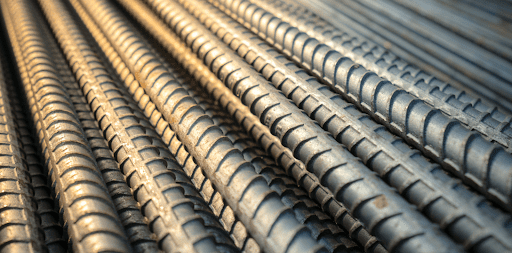

Steel TMT (Thermo Mechanically Treated) bars play an essential role in modern construction, ensuring the strength and durability of buildings and infrastructure. A key characteristic of TMT bars is their bending strength, which has a significant effect on the overall strength and lifespan of any construction project. In this blog, we will understand the impact the bending strength of steel has on construction and also its durability.

Understanding the Bending Strength of Steel

Bending strength, or flexural strength, refers to a material’s ability to resist bending forces without breaking. For TMT bars, this indicates the maximum stress they can handle before bending or failing. This property is vital for reinforced concrete structures, as it enables the bars to effectively bear loads and withstand stresses, thereby preventing structural failures.

Factors Influencing Bending Strength

Several elements can affect the bending strength of TMT bars. Let us dive in and understand those:

1. Steel Quality

Higher-grade steels like Fe500 and Fe550 offer better strength and durability when compared to lower-grade options. The steel’s chemical makeup, including the amounts of carbon, manganese, and other elements, greatly influences its mechanical properties.

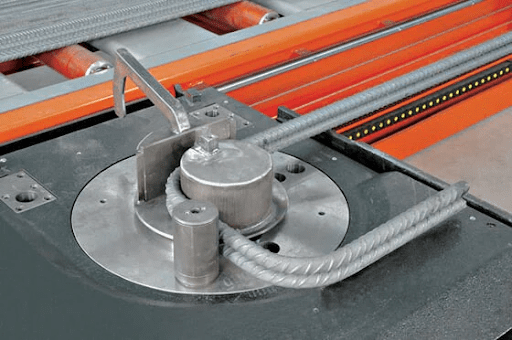

2. Manufacturing Process

The TMT process involves heating and rapidly cooling the steel, resulting in a core of martensite surrounded by a ferrite-pearlite layer. This specific microstructure boosts the bar’s strength and ductility. The techniques used during the rolling phase can impact the mechanical properties of the bars. Proper rolling ensures even stress distribution and enhances bending strength.

3. Bar Diameter

Generally, larger-diameter bars exhibit greater bending strength due to their increased cross-sectional area. However, the selection of bar diameter should align with structural design requirements and load-bearing needs.

Impact of Bending Strength on Construction Durability

Using TMT bars with high bending strength brings several key advantages to construction projects:

1. Enhanced Structural Integrity

High-strength TMT bars can withstand bending forces effectively, which helps avoid structural failures, particularly in regions exposed to earthquakes or strong winds. The increased bending strength supports the construction of taller and more complex buildings, allowing them to carry heavier loads safely.

2. Longevity and Durability

TMT bars with superior bending strength offer significant advantages in construction, as they endure environmental stresses like moisture, temperature changes, and chemical exposure more effectively. Their enhanced ability to resist bending forces ensures the structural integrity of buildings. This increased bending strength translates to improved durability and longevity, reducing the need for frequent repairs and maintenance.

3. Earthquake Resistance

High-strength TMT bars can absorb and dissipate energy during seismic activity, minimizing the risk of structural damage during earthquakes. The combination of high bending strength and good ductility allows these bars to deform without breaking, which enhances the overall performance of a structure in seismic conditions.

4. Cost-Effective Solutions

Utilizing TMT bars with greater bending strength enables engineers to design structures with fewer reinforcement bars, which can lower material expenses. Although high-quality TMT bars may require a greater initial investment, the long-term savings from reduced maintenance and improved performance often outweigh these costs.

Selecting the Right TMT Bar

When selecting TMT bars for a construction project, it’s essential to consider the following factors:

- Structural Design Requirements: The load-bearing capacity and seismic zone specific to the project will dictate the necessary bending strength of the bars.

- Building Codes and Standards: Following local building codes and international standards is essential for ensuring the safety and longevity of the structure.

- Manufacturer’s Reputation: Well-established manufacturers provide high-quality TMT bars that comply with or surpass industry norms.

- Laboratory Testing: Independent lab testing can confirm the mechanical properties of TMT bars, including their bending strength.

By choosing TMT bars with sufficient bending strength, construction professionals can secure the durability, safety, and sustainability of their projects.

Conclusion

The bending strength of TMT bars is vital for the overall efficiency and lifespan of construction projects. By comprehending the elements that affect bending strength and the advantages of quality TMT bars, engineers and contractors can make knowledgeable choices to create strong and resilient structures.

Are you looking to give your dream structures a long and durable life? Choose Jumbo TMT bars for unparalleled strength and durability!